Electrical Equipment Calibration

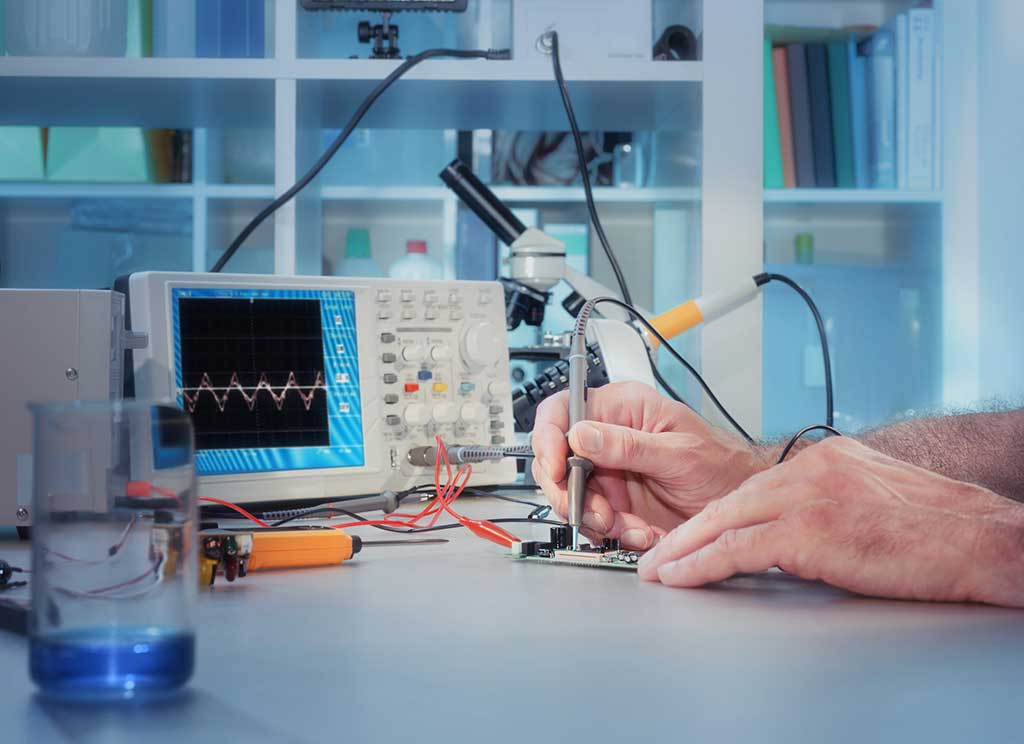

Finding a great electrical equipment calibration service can be a challenge, but with HCT Calibration, you’re in good hands. We have full ISO 17025 accreditation, meaning that you can rest assured that we have met international standards for proficiency. Our test instruments can ensure that your measurement instruments always record accurate measurements in accordance with the specification. Use our master standard today and ensure that your multimeters, oscilloscopes, power supplies and tachometers perform to the expected standard.

Remember, the quality of the firm carrying out calibration matters. Incorrect calibration can lead to you to misinterpret the output from your electrical hardware. This failure can lead to undesirable knock-on consequences, such as problems with production quality and damage to your productive assets - something that you’ll want to avoid.

Accredited with ISO 9001 Certification

Our electrical test equipment attains the highest standard. With us, your firm can meet quality assurance standards and achieve exceptional measurement accuracy without having to spend money on costly calibration equipment in-house. We are a calibration service that meets all relevant regulations and are accredited with ISO 9001 certification.

Why Calibrate Electrical Equipment?

HCT Electrical Equipment Calibration Services Process

Thanks to the scope of accreditation, HCT can service a wide variety of electrical equipment, including desktop multimeters, handheld multimeters, oscilloscopes, probes, data loggers, current clamp meters, and much much more.

To do so, we follow a strict process, ensuring that calibration is performed to a high degree of accuracy.

Here’s what we do:

Step 1: Identify Calibration Issues. It is good practice to schedule regular calibration. Having regular calibration ensures that your equipment works as intended, according to specification, every day of the year. The first step, therefore, is to find calibration issues in electrical equipment where the real measurements of devices differ from the master standard. With our accredited electrical calibration, you’ll quickly discover which equipment has fallen outside of accepted tolerances.

Step 2: Develop A Calibration Plan. The next step is to develop a plan for calibration, including steps for fixing measurement issues.

Step 3: Maintain Records. With HCT, we make it easy for your firm to maintain calibration records. These records include the results from tests, the serial numbers of equipment tested, and the status of the equipment.

When Should You Get Electrical Equipment Calibrated?

It’s a good idea to get electrical equipment calibrated on a regular schedule. Most companies choose to calibrate their electrical equipment on a monthly, quarterly or annual basis, depending on their regulatory environment, the sensitivity of their product, and their need for accuracy in the production process.

Firms should also seek calibration services in the event of an electrical shock. A shock can potentially cause damage to electrical calibration equipment, causing it to display readings outside of accepted tolerances.

Get Electrical Equipment Calibration Services From HCT Calibration Today

If you haven’t set up a calibration service for your electrical equipment yet, then don’t wait until there’s a problem: get help from trusted and accredited calibration experts at HCT today. With us, you can comply with regulatory standards and avoid costly fixes in the future.